Introduction

In the field of industrial process instrumentation, radar level transmitters have revolutionised the way businesses monitor and control liquids, masses, emulsions, and other chemical levels. These advanced devices, such as the Nivelco PiloTREK WP200 Integrated Radar Level Transmitter, offer many benefits that have proven to be vital across various industries.

Unmatched Accuracy and Reliability

One of the most significant advantages of radar level transmitters is their exceptional accuracy in liquid level measurements. Utilising radar wave technology, these transmitters can precisely determine the distance from the liquid surface to the sensor, providing accurate readings regardless of environmental conditions.

The new PiloTREK WP–200 non-contact radar level transmitters use the most advanced industrial measurement technology, the 80 GHz FMCW radar. The important advantage of 80 GHz radars compared to lower frequencies is the smaller antenna size, better precision, and narrow beam angle. The PiloTREK WP–200 provides measurement results with millimetre accuracy.

Non-Contact Measurement

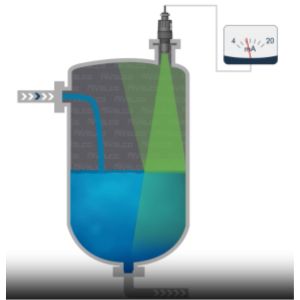

Radar level transmitters offer non-contact measurement capabilities, setting them apart from traditional level measurement methods that require direct contact with the surface. By utilising pulsed radar waves, the WP200 Integrated ensures that there is no physical interaction with the product, eliminating the risk of sensor contamination or corrosion.

Wide Application Range

The versatility of radar level transmitters makes them suitable for a wide range of level monitoring applications. From small tanks to large storage vessels, the PiloTREK WP200 can handle measurement distances of up to 30 meters, making it applicable in diverse industrial settings. It effectively measures liquids, masses, emulsions, and other chemicals widely used in, for example, the water industry, food industry, energy industry, pharmaceutical industry, and chemical industry.

Advanced Signal Processing and Echo Filtering

The PiloTREK WP200 Integrated is equipped with advanced signal processing and echo filtering capabilities, enabling it to overcome obstacles such as agitated surfaces, foam, or vapor. These features ensure that the device delivers accurate and stable measurements, even in challenging conditions. By eliminating false echoes and interference, businesses can rely on consistent data, leading to improved process control and operational efficiency.

Easy Integration and User-Friendly Interface

Incorporating the PiloTREK WP200 into existing industrial automation systems is seamless and straightforward. With communication options like 4-20mA, HART, and Modbus, the device can effortlessly connect with PLCs, SCADA systems, and other control systems. Additionally, the transmitter’s user-friendly interface, equipped with a clear LCD display and intuitive menu navigation, simplifies device configuration and calibration. This reduces installation time, minimizes operator training requirements, and enhances overall productivity.

Enhanced Safety and Cost Efficiency

Accurate liquid level monitoring not only optimizes operational efficiency but also enhances safety measures. The PiloTREK WP200 helps prevent overfilling or underfilling of tanks, mitigating potential hazards and environmental risks. By reducing the likelihood of spills and leaks, businesses can avoid costly clean-up operations and equipment damages, resulting in significant cost savings in the long run.

Conclusion

In conclusion, radar level transmitters, such as the PiloTREK WP200 Integrated, have revolutionised liquid level monitoring. With high accuracy, non-contact measurement and a user-friendly interface, it’s an asset for industries seeking efficiency and safety.