When it comes to measuring the flow rate of bulk solids, there are a few different technologies available. Two of the most popular are inline microwave bulk solids mass flow meters and impact weighers. Here are some reasons why you will prefer an inline microwave flow meter, or MF-3000, over an impact weigher:

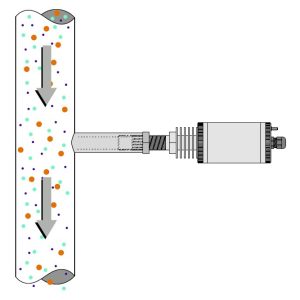

1. Non-contact measurement: Unlike an impact weigher, the MF-3000 measures the mass flow rate of bulk solids in a pipe without coming into contact with the material. The MF-3000 is designed to be non-intrusive and low maintenance, while an impact weigher requires contact with the material being measured, which can lead to increased wear and tear on the equipment.

2. High accuracy: The MF-3000 typically has a higher accuracy than an impact weigher, with accuracy levels ranging from 1% to 2%, depending on the material being measured. This makes it suitable for use in applications that require very precise measurement.

3. Continuous measurement: The MF-3000 provides real-time measurement of the mass flow rate of bulk solids, making it ideal for use in process control and monitoring applications. This makes it ideal for use in continuous processes where any disruptions could lead to significant problems.

4. Ease of installation: Installing an MF-3000 mass flow meter is typically easier and less disruptive than installing an impact weigher. The MF-3000 can be installed in an existing pipeline, without the need for modifications to the system.

5. Wide range of applications: The MF-3000 is suitable for measuring the mass flow rate of a wide range of materials, including grains, powders, dust, granules and pellets. It can be used in industries such as food processing, pharmaceuticals, chemicals, and more.

Conclusion

In summary, the MF-3000 bulk solids mass flow meter offers several advantages over an impact weigher, including non-contact measurement, high accuracy, continuous measurement, ease of installation, and suitability for a wide range of materials and applications.

MF-3000 Bulk Solids Mass Flow Meter

Our solids flow meter MF 3000 is designed for bulk-solids flow measurement in metallic pipes from a few kg/h to many t/h. The system is suitable for on-line measurements of powders, dusts, pellets, and granules from 1nm up to 20mm in pneumatic or free fall conditions. The measurement principle of the MF 3000 is based on the Doppler-Effect, where the sensor generates a uniform field in the micro…